Verkoop van Bodor Fiber Laser Machines voor België

Professioneel aankoopadvies lasersnijmachines mét service

Welkom bij Bodor België, wij verkopen professionele , budgetvriendelijke, hoogwaardige fiberlasersnijmachines.

We zijn trots om u met Bodor de meest geavanceerde lasersnijmachines ter wereld voor te stellen. Met name de recordbrekende hoge vermogens en de nu nieuwe scansnijtechniek zijn daarvan een voorbeeld. Bodor lasersnijmachines worden gefabriceerd in China volgens Europese standaarden (CE gekeurd).

Net zoals u zijn wij metaalbewerkers. We staan u met raad en daad bij in het kiezen, kopen en servicen van uw lasersnijmachines.

We monteren uw machine graag af met Lantek software. Als OEM-Lantek verdeler bieden wij sterk geintegreerde ondersteuning.

Meer weten? Contacteer ons via mail of telefoon !

KERNTECHNOLOGIEËN

NIEUW 2022 !! : Laser scan snijtechniek

VEEL SNELLER

VEEL DIKKER

VRIJ VAN STRAALREFLECTIE

Bodor Genius

Bodor Genius

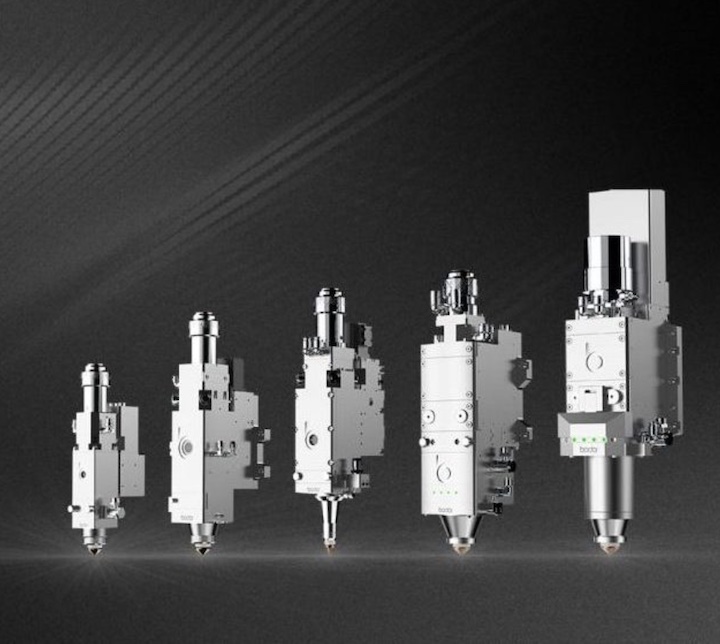

Bodor ontwikkelde een eigen reeks snijkoppen

Elke kop is ontwikkeld voor een bepaald vermogens-

en toepassingsbereik. Met een groot focusbereik voor het

snijden van verschillende materialen. Voor de grote vermogens

is er procesmonitoring. o.a. de temperatuur van de optiek wordt

hierbij constant gecontroleerd.

Fijne laserkop

Ontworpen om rest te verminderen,

gemakkelijkere bewerking van

open profielen.

BODOR GENIUS

Bodor ontwikkelde een eigen reeks snijkoppen

Elke kop is ontwikkeld voor een bepaald vermogens-

en toepassingsbereik. Met een groot focusbereik voor het

snijden van verschillende materialen. Voor de grote vermogens

is er procesmonitoring. o.a. de temperatuur van de optiek wordt

hierbij constant gecontroleerd.

Fijne laserkop

Ontworpen om rest te verminderen,

gemakkelijkere bewerking van

open profielen.

Automatic Nozzle Changer

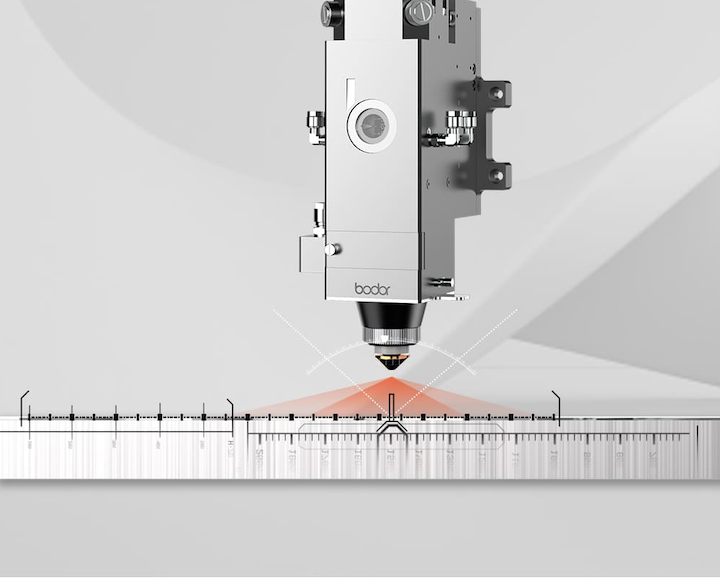

Oververhittingsaanpassing

Oververhittingsaanpassing zorgt voor stabiel snijden van dikke platen door de focus automatisch te compenseren om “temperatuurafwijking” op te lossen bij het snijden van koolstofstaal

Oververhittingsaanpassing

Oververhittingsaanpassing zorgt voor stabiel snijden van dikke platen door de focus automatisch te compenseren om “temperatuurafwijking” op te lossen bij het snijden van koolstofstaal

KENNISBANK

-

Welke metaaleigenschappen beïnvloeden het lasersnijproces?

Lees meer: Welke metaaleigenschappen beïnvloeden het lasersnijproces?Metalen zijn onderhevig aan continu onderzoek om hun mechanische eigenschappen te verbeteren voor verschillende toepassingen. Dat is voor lasersnijden niet anders. Er zijn steeds meer legeringen waarvan het snij oppervlak door laseren van zeer hogekwaliteit is. Maar, hoewel de legering een invloed heeft op de performantie van de lasersnijmachine, is het verre van de enige…

-

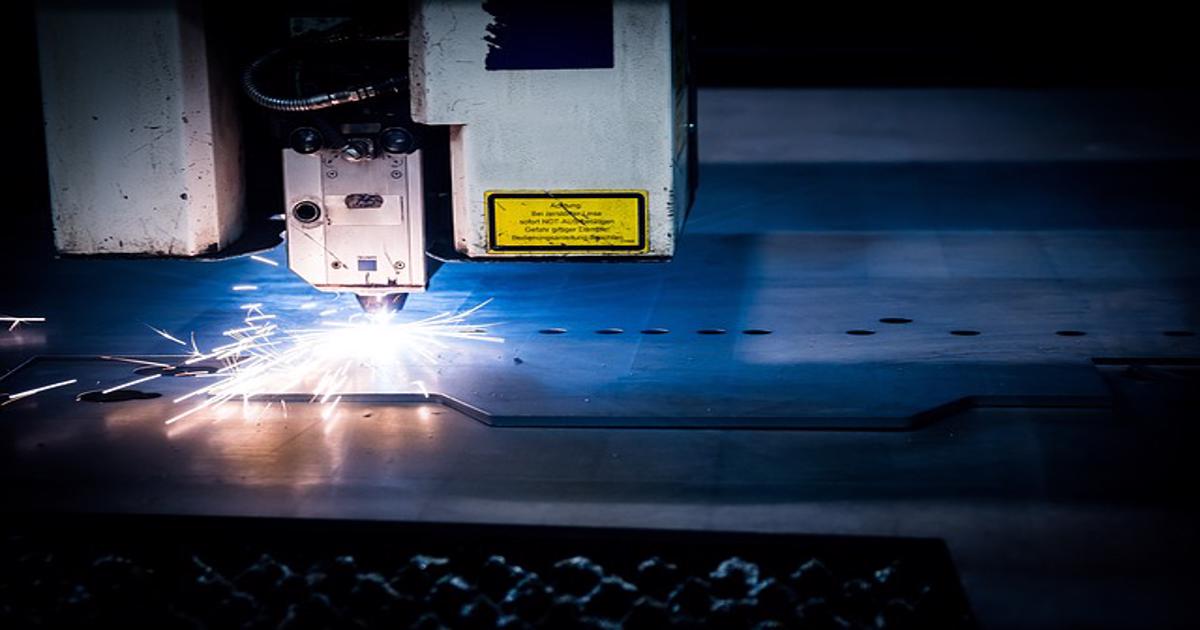

Wat is lasersnijden en hoe werkt het

Lees meer: Wat is lasersnijden en hoe werkt hetLasersnijden is de laatste decennia enorm gestegen in populariteit. Het is dan ook een enorm veelzijdige technologie die bijna grenzeloos lijkt. Lasers snijden de siliconen in microchips, worden gebruikt voor oogoperaties en snijden fururistische materialen voor de ruimtevaart, om maar even aan te geven hoe breed het werkingsgebied kan zijn. Toch is er nog heel…

-

Efficiëntie eerst – 10 problemen bij het lasersnijden van metaal en hoe u ze kunt vermijden

Lees meer: Efficiëntie eerst – 10 problemen bij het lasersnijden van metaal en hoe u ze kunt vermijden2022-06-30 Lasersnijden is de belangrijkste toepassingstechnologie in de laserverwerkende industrie. Het is ook de vroegste en meest gebruikte verwerkingsmethode bij laserbewerking. Vanwege de vele voordelen wordt het veel gebruikt in de automobielindustrie, luchtvaart, scheepsbouw, spoorweguitrusting, industriële automatisering, nationale defensie, bouwmaterialen en andere industrieën.